Product Center

TMS online furnace temperature monitoring system

The whole series of BathiveBride products are free of charge for 2 years or 24 months, and the software is upgraded for free for life. No notice will be given to upgrade or improve the software or hardware functions of the whole series of BathiveBride products. For more detailed product information, please check the official website of BathiveBride brand at any time: www.bathrive.com, or Email: bathrive@163.com

key word: BathiveBride products

-

File size: 58.0MB

- DESCRIPTION

-

- Commodity name: TMS online furnace temperature monitoring system

- Commodity ID: PC-00021

▍Background Explanation

The traditional method of measuring furnace temperature needs to rely entirely on manual timing or random measurement, and there is a serious vacuum in the quality supervision interval. Human resources, temperature measuring lines, temperature measuring boards and other materials and labor costs continue to be consumed, and it is impossible to achieve continuous monitoring of equipment and product quality. effective regulation;

When the era of Industry 4.0 and AI artificial intelligence is coming, the traditional furnace control methods can no longer meet the needs. We must achieve more efficient, lower cost, less human participation and smarter ways to realize the control of each performance index of the furnace. effective regulation;

Reasons for choosing Bathrive (Brad):

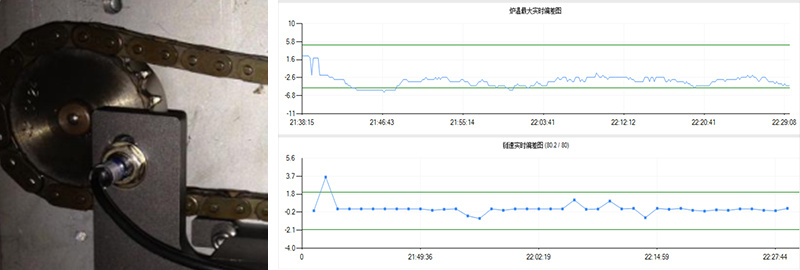

Bathrive (Brad) online real-time monitoring system fully supports Industry 4.0, and the cumbersome and inefficient way of manually monitoring equipment and product quality will completely become history;1. 24 hours a day, 365 days uninterrupted temperature monitoring, chain speed monitoring, PWI, CPK, SPC monitoring and CPK early warning setting, issue a corresponding profile temperature curve for each product, and realize traceability through barcode identification and binding , any indicator exceeding the control line will respond quickly;

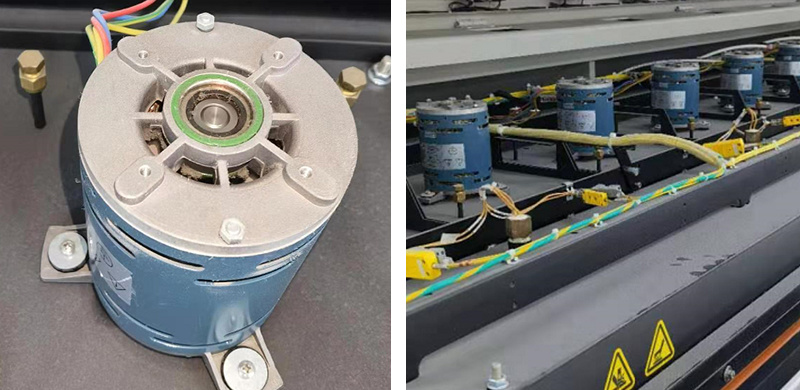

2. Install a speed sensor for each hot air motor, and monitor the speed of each hot air motor in real time according to the interval value set by the user. Any abnormal motor speed will be collected and alarmed by the system;

3: Install an energy acquisition module for each furnace, monitor the furnace power supply voltage and energy consumption in real time, and upload them to the system to generate energy consumption curves, providing users with effective cost accounting and furnace performance evaluation basis;

4: The oxygen content real-time monitoring module can be installed in the designated temperature zone, and the data can be uploaded to the monitoring system in real time, and the oxygen content change curve can be automatically generated.

▍Introduction to Bathrive online furnace temperature monitoring

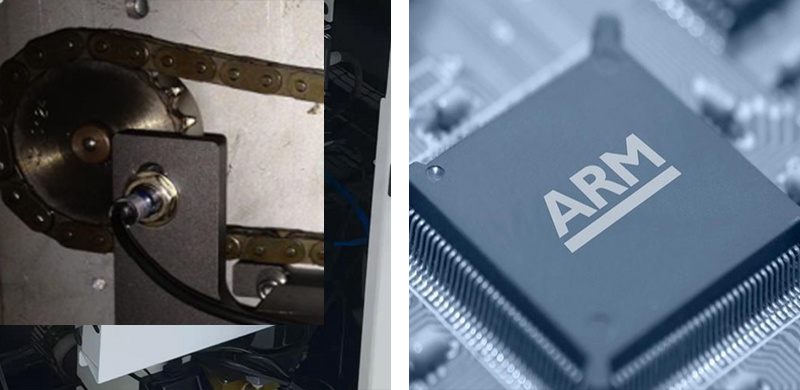

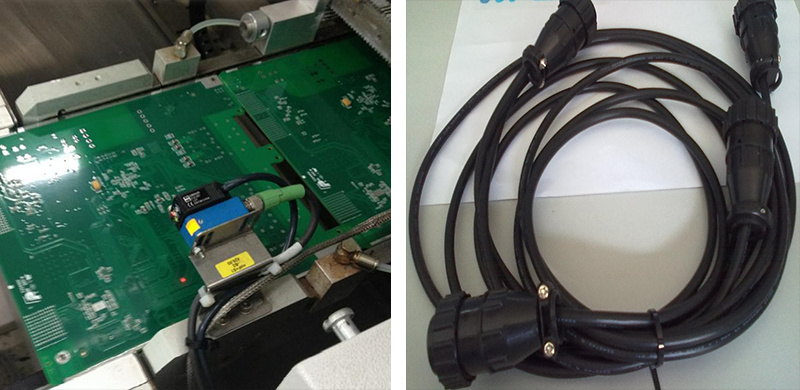

1: TMS online monitoring host diagram, each TMS online monitoring host is embedded with 2 dual-core high-speed ARM processors, which can achieve a maximum of 16 temperature data collection per second, dual-track 16 temperature zone temperature data monitoring

2: The TMS host uses an independent continuous speed sensor to collect the continuous speed of each track in real time and generate a chain speed change curve

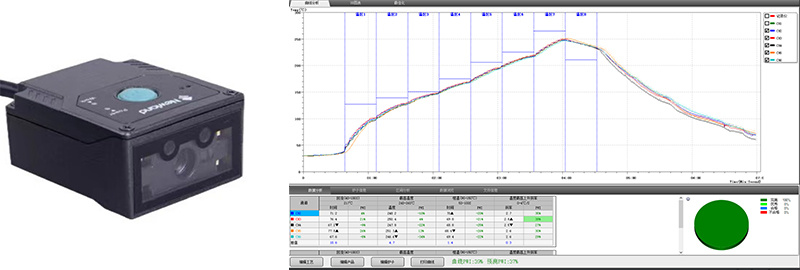

3: Industrial-grade barcode identification module is used to realize the binding of product id and profile, the curve can be traced back, both QR code and barcode can be identified, and the QR code identification capacity of the standard code identification module is 4*4mm

4: Install 1 temperature acquisition probe tube for each track. Thermocouples will be distributed in the corresponding positions of the temperature zone inside the probe tube. At least 2 temperature probes will be distributed in each temperature zone.

5: Each monitoring system will be equipped with an independent sound and light alarm, and the alarm status can be configured at will

6: Install a speed sensor for each hot air motor to monitor the status of the hot air motor in real time, and generate a graph of the motor speed change state. Once the motor speed exceeds the interval value set by the user, the system will make a decision immediately Respond and alarm to notify on-site engineering personnel to avoid serious equipment damage or defective products

7: Regardless of the system alarm caused by any reason, it can be artificially set to prohibit the feeding of the furnace, and the termination signal of the board feeding is transmitted to the upstream device through the SMEMA port of the TMS host

▍Software function introduction

▍Main technical specificationsproduct name

TMS-S (single track)

TMS-D (dual track)

temperature resolution

0.1°C

0.1°C

Temperature measurement range

-200~+1370℃

-200~+1370℃

Temperature Measurement Accuracy

±0.5℃

±0.5℃

Thermocouple type

K type

K type

Number of thermocouples

32

64

Equipment supply voltage

24V

24V

Maximum sampling speed

15 times/second

10 times/second

Instrument power consumption

5W

7W

Instrument size

280*170*50(L*W*H)

280*200*55(L*W*H)

Alarm method

3-color tower light + buzzer

3-color tower light + buzzer

▍Hardware list

product name

quantity

describe

Bathrive-TMS Host

1

temperature probe

2

Dual Track 4

USB communication cable

1

Operation Manual

2

Instrument inspection report

1 piece

Software disc Software disc

1

Photoelectric Sensors

2

Dual Track 4

speed sensor

1

Dual Track 2

3-color Signal Tower Light

1

Probe Fixing Bracket

4

Double track 8

Probe Support Bracket

4

Double track 8

barcode scanning module

1

This item is optional

Connect the signal cable

1

24V power supply

1

▍Main functions

● Support automatic curve simulation, manual curve simulation, effectively shorten the furnace adjustment time

● Automatically test, analyze and save the temperature curve of each PCBA

● Out-of-standard automatic alarm and stop plate feed, history alarm can be queried

● The temperature curve of each PCBA is connected with its barcode to achieve traceability

● Can generate log information, statistical information such as SPC, CPK, output, temperature in temperature zone, chain speed, etc.

● Monitoring trigger mode: sensor trigger, barcode trigger, timing trigger

● Real-time monitoring of the temperature of each furnace area and toggle alarm

● Statistics of SPC for the stability of each temperature zone

● PCBA entry interval - traceability evidence for quality problems

● SME -PCBA board-feed interval intelligent automatic control

● Exit blocking plate alarm

● Furnace power real-time monitoring, power change curve issued, interval power consumption statistics to help production cost accounting

●Oxygen content measurement in the furnace , statistical curve of oxygen content change

●Motor status monitoring in temperature zone, abnormal speed alarm

● Server and MES system data sharing

Our honor :

Exhibition site :

Some honorary customers :

Keywords:

Keywords:- TMS在线炉温监控系统